NO-DEW anti-condensation functions on sheet metal applications

NO-DEW anti-condensation is a self-adhesive felt for lamination to ceilings and walls in single-layers laminates |

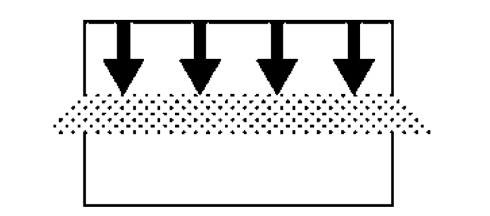

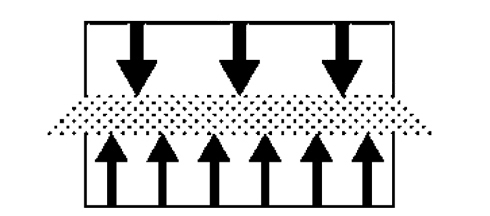

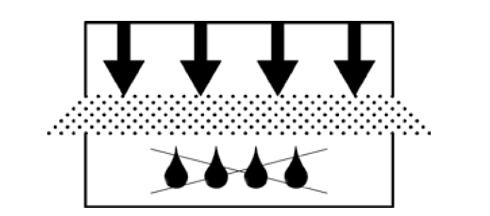

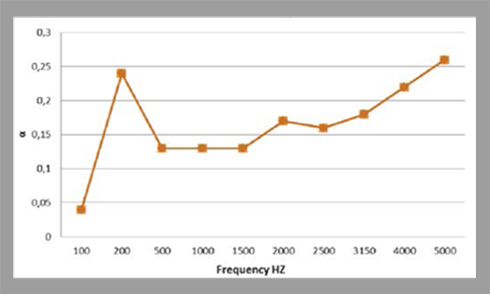

NO-DEW anti-condensation by Barbiflex is an adhesive felt for sheet metal roof insulation: it is specific for lamination to ceilings and walls in single-layer laminates, ideal to prevent the damage that can cause moisture in buildings, in particular on metal and non-ferrous metals roofs. NO-DEW is an anti-condensation film composed of polyester fiber, hot melt adhesive based on synthetic rubber and PE protection foil. NO-DEW guarantees, even with a very limited thickness, the maximum absorption of the condensation, in addition to a remarkable microbiological resistance even at extreme temperatures. NO-DEW prevents dripping of water from condensation, absorbs noise, resists aging and additional protection against corrosion. NO-DEW is self-adhesive and is applied to the metal panel in the process of profiling, arriving on the construction site ready to be laid directly with the cover panels, to have insulated panels: simple to operate, long-lasting and, above all, extremely effective, it is perfect for applications on corrugated sheets (self storage isolation, industrial plants isolation, agricultural buildings isolation , garages isolation).

|

|

| Technical Instructions >> |

|

|||